All our machinery is designed and manufactured in Barneveld, the heart of the Netherlands, supplement by certified suppliers from the nearby areas.

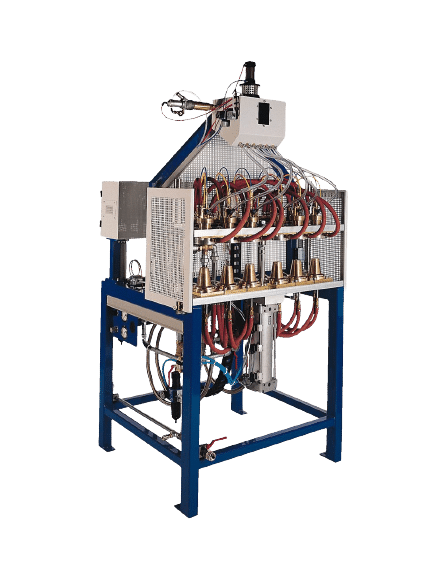

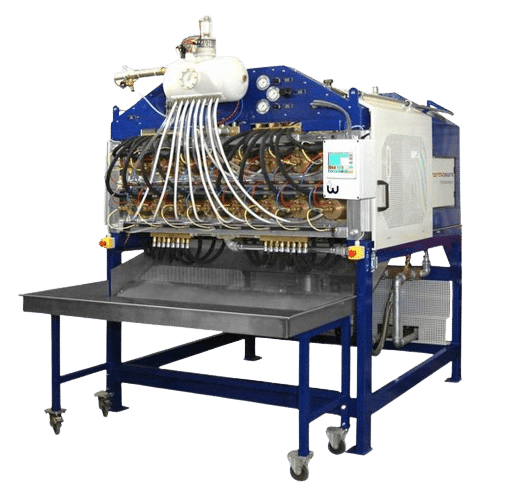

Our machines are used to serve our customers in the best possible way, build with quality components, solid and durable constructions, high class electrical systems, latest software and modern electronics.

The dry foam technology, as a defining element of our core business, enables our customers to produce thin-walled foam products with optimal fusion, smooth surface and complete freedom of design.

Based on product type and shape, material choice, production volume and mode of automation, a careful choice is made with you from our machine range. With the specifications of use, our machines can be made suitable for the use of raw materials such as EPS, EPP, co-polymers, ETPU and various types of bio-foams.

For maximum flexibility, optimum energy management and efficiency, our moulds are generally designed as single cavity moulds. Sophisticated mounting options allow the moulds to be mounted on any machine.