Pre-Expansion

Pre-expansion is of great importance as the starting point for optimal manufacturing of foam packaging products. We offer a wide range of pre-expanders with varying capacities.

Thermoware offers a wide range of machines, which enable you to produce premium thin-walled and complex foam parts.

Our machinery covers all aspects of the production and packaging process.

You can choose any combination, which suits your business goals best.

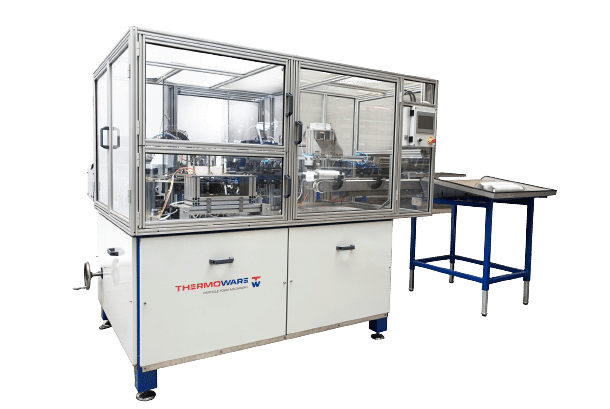

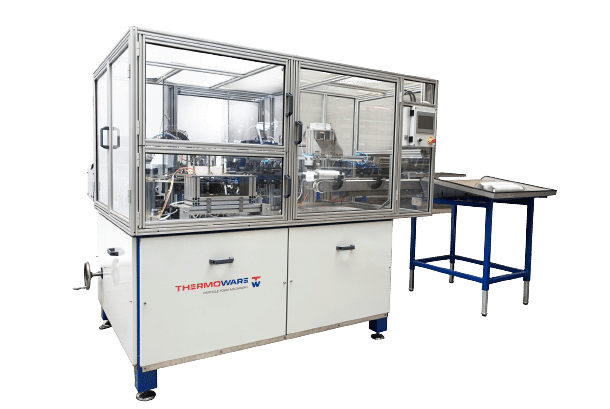

Our high speed leak testers have been designed to test all kind of EPS cups and comply with the quick leak test method.

A team of dedicated Thermoware engineers designed several labelling solutions on behalf of our customers.

Our high speed leak testers have been designed to test all kind of EPS cups and comply with the quick leak test method.

A team of dedicated Thermoware engineers designed several labelling solutions on behalf of our customers.

When you need a spare part, whether it’s a complete mould or a spare part for one of your machines or moulds, you can rely on Thermoware. Continuity is key in your production process. That is why our machines stand out in reliability.

When you need a spare part, whether it’s a mould or a spare part for one of your machines, you can rely on Thermoware as well. We ship spare parts to all places in the world.

Our colleagues are available to meet and discuss all possible options together.