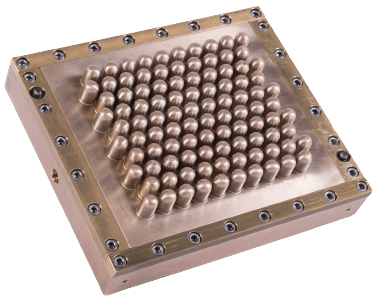

The ability to manufacture thin and complex foam parts

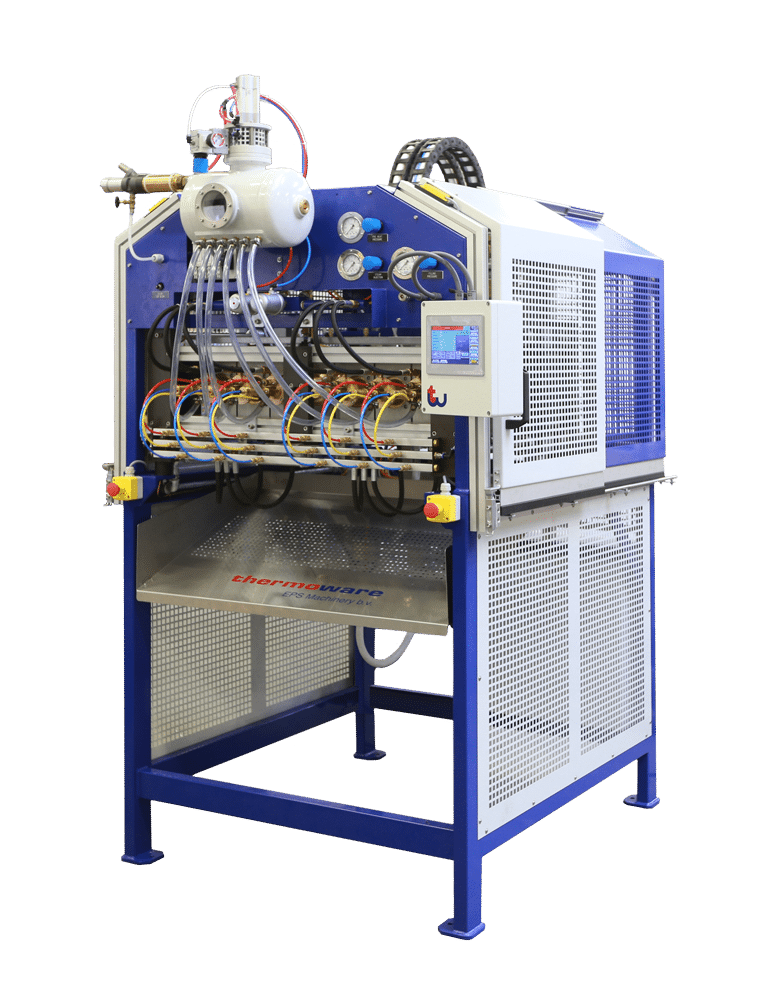

In the dry moulding process, single molds are commonly used to ensure optimal filling and steaming of all cavity parts.

Customized filling systems further enhance the cavity filling, while indirect heating and the absence of condensate and moisture lead to perfect fusion of the beads, even in very thin segments.

This method offers significantly more control over the process, allowing for optimal tool settings and superior product quality.