We offer a wide range of pre-expanders with varying capacities.

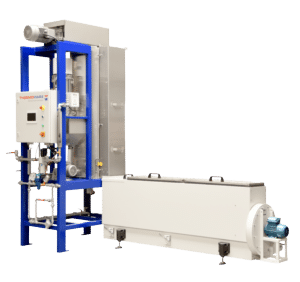

The automatic processing cycle begins with the inlet of raw material into the expansion chamber through the dosing hopper.

The expanded material, coming out from the expansion chamber, will be discharged by gravity into the fluidized bed and dried by means of hot air blowing. From here, the material will be conveyed to the storage silos.

Machine control is made by a main electro-mechanical and digital panel.

A precise measuring and adjustable steam/air flow device in combination with a rockwool insulation cover of the expansion chamber assures a very cost-effective use from the perspective of energy consumption.

Interested in optimizing your manufacturing efficiency and reducing energy costs? Reach out to our team for more details.